Transform Your Crushing Tools: Check Out Diverse Models of Impact Crusher for Sale

Transform Your Crushing Tools: Check Out Diverse Models of Impact Crusher for Sale

Blog Article

Revolutionize Your Recycling Procedures With an Influence Crusher

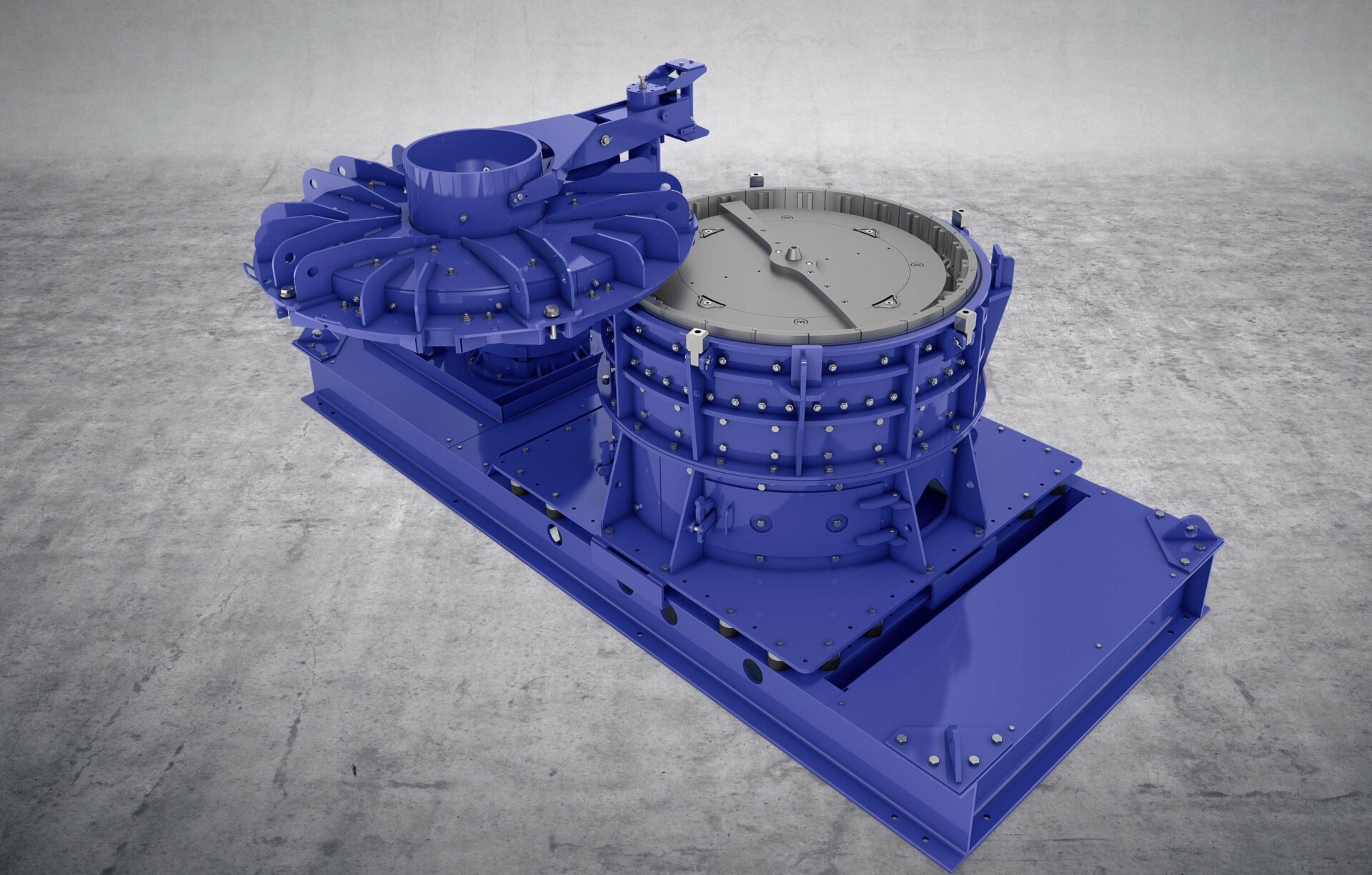

One such service that has actually gained considerable interest is the impact crusher. How precisely does an influence crusher work, and what are the advantages it can supply? In this discussion, we will certainly check out the internal operations of an influence crusher, the kinds of materials it can process, and offer tips for optimizing its efficiency.

Exactly How an Effect Crusher Works

An influence crusher runs by making use of a high-speed blades and a crushing chamber to efficiently break down products right into smaller sized, more manageable dimensions. The rotor is furnished with dealt with or replaceable hammers, relying on the wanted dimension of the end product. As the rotor spins at broadband, the hammers strike the material, creating it to disintegrate. The fragmented product then gets in the squashing chamber, where it is more minimized in size by the influence forces created by the turning rotor. This procedure is duplicated multiple times till the wanted size is accomplished.

One of the vital benefits of an impact crusher is its capability to create a consistent fragment form. Unlike various other squashing approaches, such as jaw crushers, which often tend to generate even more elongated particles, influence crushers develop cubical-shaped bits. This is because of the high-speed effect forces produced by the blades, which efficiently shatter the product and produce a more regular item.

Furthermore, impact crushers are very flexible devices that can manage a broad variety of products. From soft and friable products like limestone to difficult and unpleasant materials like granite, impact crushers can effectively process different kinds of materials. This makes them excellent for use in recycling procedures, where various types of materials need to be processed and transformed right into recyclable items.

Advantages of Making Use Of an Effect Crusher

With its capability to create an uniform bit form and take care of a large range of materials, the effect crusher uses a multitude of benefits in different recycling operations. The influence crusher makes use of a high-speed effect pressure to break down products, resulting in a more reliable and cost-effective procedure compared to various other crushers.

One more advantage of utilizing an impact crusher is its adaptability. By generating consistent particle dimensions, the effect crusher makes sure that the recycled products can be used for different functions, such as road construction or as aggregate in brand-new concrete.

Sorts Of Materials That Can Be Refined

The influence crusher is qualified of processing a large variety of materials, making it very flexible in reusing operations. One of the primary materials that can be processed by an effect crusher is concrete. The ability like this to refine such a large array of products makes the impact crusher a vital tool in reusing operations, making it possible for the recovery and reuse of important sources while minimizing waste and environmental influence.

Tips for Optimizing Effectiveness With an Influence Crusher

To maximize the efficiency of an influence crusher and attain optimal effectiveness, drivers ought to implement several essential methods. Primarily, normal upkeep is important. This consists of routine assessments of the machine to recognize any potential problems or worn-out components that may impact its performance. Operators must also make certain that the effect crusher is correctly lubed to minimize rubbing and stop unnecessary deterioration.

Another vital pointer is to adjust the crusher settings according to the certain requirements of the material being refined. This can be done by keeping an eye on the feed size, the rate of the rotor, and the gap between the impact plates. By fine-tuning these settings, operators can make sure that the crusher is operating at its ideal capability and creating the preferred result size.

In addition, drivers ought to thoroughly select the wikipedia reference appropriate feed product for the impact crusher. This involves comprehending the attributes of the product and its impact on the crusher's efficiency. It is necessary to stay clear of feeding oversized or exceedingly tough materials that might cause damage to the equipment or cause ineffective squashing.

Finally, operators ought to on a regular basis keep track of the efficiency of the influence crusher and make modifications as essential. This can be done by evaluating the product quality, production price, and power usage. By continuously optimizing the crusher and assessing's performance, drivers can make best use of efficiency and lower downtime.

Ecological Influence of Using an Influence Crusher

Regularly monitoring and maximizing the performance of an influence crusher not only makes best use of performance and minimizes downtime, but it additionally enables drivers to examine and reduce the environmental impact of utilizing the crusher. The environmental effect of using an effect crusher can be significant, specifically if proper procedures are not taken to lessen it.

To alleviate this influence, drivers can carry out various procedures. Additionally, normal maintenance and assessment of the crusher can aid recognize and attend to any kind of concerns that might lead to raised dirt exhausts.

One more environmental concern is the noise produced by the effect crusher. Excessive sound can interrupt close-by homeowners and wild animals, and it can likewise have negative health and wellness results on the operators operating in close closeness to the crusher. To decrease noise pollution, drivers can make use of noise-reducing procedures such as or enclosures around the crusher. They can also schedule crushing procedures throughout times when sound influence is minimized, such as throughout daytime hours when sound from bordering activities is greater.

Verdict

Finally, incorporating an impact crusher into recycling operations can revolutionize the process by effectively squashing different products and improving efficiency. The benefits of using an influence crusher consist of lowered waste volumes, enhanced manufacturing rates, and enhanced item quality. By complying with tips for taking full advantage of effectiveness and considering the ecological impact, reusing operations can substantially gain from using an influence crusher.

The impact crusher makes use of a high-speed influence force to damage down products, resulting in an extra efficient and economical process compared to various other crushers. The ability to process such a vast array of products makes the impact crusher a vital tool in recycling procedures, allowing the healing and reuse of useful sources while lowering waste and environmental impact.

Regularly monitoring and check out this site maximizing the efficiency of an influence crusher not just maximizes performance and reduces downtime, yet it additionally permits drivers to evaluate and minimize the ecological impact of utilizing the crusher. The ecological influence of utilizing an impact crusher can be substantial, especially if proper actions are not taken to lessen it. By complying with ideas for maximizing effectiveness and considering the ecological impact, reusing procedures can considerably benefit from the use of an influence crusher.

Report this page